Merchant Automotive Front Transfer Case Housing - 263XHD | 2001 - 2007

Our Guarantees

Product Information

-

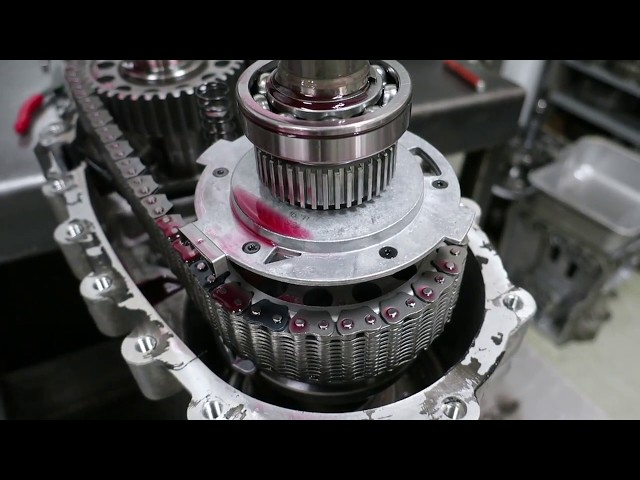

This is a NEW Front Case Half for a GM NP263XHD transfer case found in 2001 to 2007 GM Duramax vehicles. The Front Case Half includes input and front output bearings as well as the planetary ring gear already installed in the case half.If your NP263XHD front case half is cracked or broken this is the correct replacement part for you. Excessive driveline vibration from a bent or damaged drive shaft or failing U-joint can potentially lead to transfer case damage including a cracked or broken front case half which carries the full weight of the transfer case at the front mounting studs. To protect your transfer case and transmission output housing we strongly recommend installing a Merchant Automotive Rear Housing Support. Click here for the Rear Housing Support for 2001 to 2007 Allison equipped trucks. Click here for the Rear Housing Support for 2001 to 2006 ZF6 equipped trucks.

NOTE: This Front Case Half is for electronically shifted NP263XHD transfer cases only! It will not fit NP261XHD transfer cases that are easily identified by their floor mounted manual shifter. It will not fit HD model transfer cases either.Click here to view the RTV Silicone needed to seal the case halves when reassembling.Click here to view the Merchant Automotive Transfer Case Pump Upgrade kits.

To view/download Pump Upgrade installation instructions click here.

To view the Merchant Automotive Pump Upgrade installation video click here.

To view the Truck U segment on the Merchant Automotive Transfer Case Pump Rub kit click here.

What is a Transfer Case “Pump Rub” Failure?

GM transfer cases used from 1998 through early 2007 use a gear pump inside the case that is driven off the mainshaft. The pump forces oil to the planetary as well as the drive sprocket sleeve. Because the pump is driven by the shaft, the housing of the pump must "float" in the rear housing. There are tabs around the pump housing that fit into spots in the rear housing to locate the pump housing and prevent it from spinning inside the case with the mainshaft. Over time, the pump tabs can start to wear on the rear housing. GM installed a spring steel clip in the housing intended to prevent wear, but the clip can break and be rendered useless.

Since the pump housing is aluminum and is a harder material then the magnesium rear housing, it can wear a hole in the rear housing and cause a very small leak. This leak is frequently high enough on the case that it typically will not leak when vehicle is not moving and therefore not leaving any drops on the ground; it will however leak while the vehicle is in motion. Unfortunately, since the transfer case does not have a low fluid indicator the pump rub failure is often not found until there is transfer case damage from running the case out of fluid.

Avoid costly repairs to your transfer case by preventing “Pump Rub” by installing a Merchant Automotive Transfer Case Pump Upgrade kit in your transfer case today, before it happens to your vehicle.

With installation of this kit, you will have a LIMITED LIFETIME WARRANTY against pump rub. If your case ever wears a hole in the new rear housing with the upgrade installed. We will buy you a new transfer case. However, if you already have a hole in your case, we recommend installing a new rear housing for a complete repair. The MA Lifetime Warranty will only apply to installations with a new rear housing.

FAQ:

I hear a grinding noise at low speed after reassembling my transfer case. What could that be?

A low speed grinding noise is most commonly caused by the rear output bearing snap ring not being fully seated causing the bearing to move out of proper alignment. Verify that the snap ring is fully engaged and properly seated in the rear housing and the locating groove in the bearing.

What would cause a speed sensor correlation code after reassembling the transfer case?

A speed sensor correlation code is often accompanied by a low speed grinding noise and is frequently caused by the rear output bearing snap ring not being fully seated causing the bearing to move out of proper alignment. Verify that the snap ring it fully engaged and properly seated in the rear housing and the locating groove in the bearing.

What fluid should I use in the transfer case and how much is needed?

We recommend our Performance Transfer Case Fluid for use in ALL transfer cases and have seen improved performance over the factory recommended ATF or other alternate oil recommendations. Two-quarts are required to fill the NP261HD, NP263HD, NP261XHD and NP263XHD transfer cases.

How tight do I tighten the transfer case mounting nuts for the NP261XHD and NP263XHD at the transmission output adapter?

The factory recommended torque specification is 37 ft-lbs for the transfer case adapter nuts for both the NP261XHD and NP263XHD.

How tight do I tighten the transfer case assembly bolts for the NP261XHD and NP263XHD securing the case halves together?

The factory recommended torque specification is 27 ft-lbs for the transfer case assembly bolts for both the NP261XHD and NP263XHD.

Can my original transfer case gasket be reused if it is not ripped?

We recommend replacing the transfer case gasket any time the transfer case is removed from the transmission output adapter. It is cheap insurance against leaks that not only make a mess but could also damage your transmission!